|

| |

Tracecut software

Tracecut is much more than just a data capture system. It

provides the user interface for setting up digitising parameters & enables

you to manipulate data then create a CNC programme or CAD output. It also

features a dimensioning module which gives you the ability to measure components

and print out an inspection report. There are also other application specific

modules for turbine blade refurbishment & IGES surface generation.

Tracecut

enables you to define planes & align axes & has a full range of datum

functions which means that you can set up jobs rapidly & easily without the

need for complex fixtures.

A variety of data capture methods are

available:-

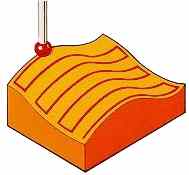

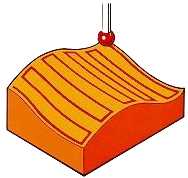

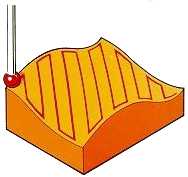

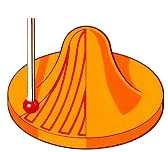

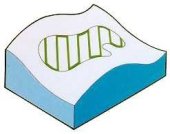

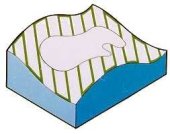

2D Profiles

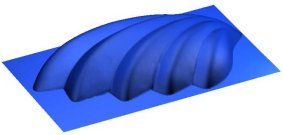

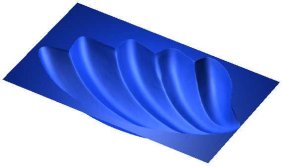

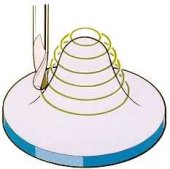

3D X Axis Parallel 3D Y Axis Parallel

3D Any Angle

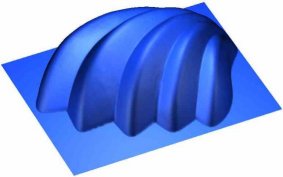

3D Radial

The different methods of data capture enable us to set up the Cyclone

in the most efficient way to suit the geometry of the part to be

digitised.

Tracecut

gives you the power to manipulate digitised data in many ways:-

Original Male to Female

Scale Independently in X, Y, Z

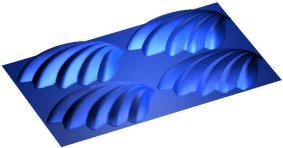

Combine for

Multi-Impression Tooling

Merge for New designs

You can use any type of cutter:-

The geometry of the cutter can be completely different to that of the

stylus used for digitising.

You

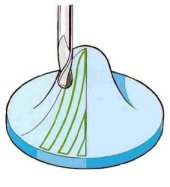

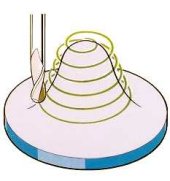

can choose from a variety of cutter path strategies:-

The toolpath can be completely different to the method used for

digitising; multiple toolpaths using different tools, e.g. roughing, semi-finish

& finish can be created.

2D profiles can be used as boundaries to restrict cutter paths to

certain areas only.

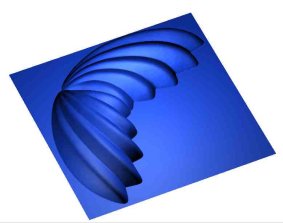

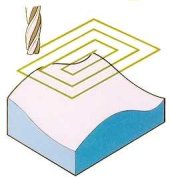

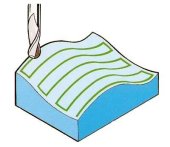

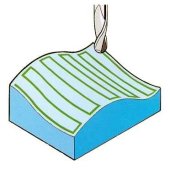

Terrace

X Parallel Y Parallel

Machining Boundary

Exclusion Zone

Radial

Spiral Circular

Key Benefits

- Tracecut breaks the

traditional copy milling link between stylus & cutter. You can create

your CNC programme, with the tool shape, diameter & machining path

being totally independent of the stylus diameter & scan path used for

digitising.

- You can apply a negative or

positive offset to the surface to allow for a spark gap or material

thickness.

- You can create any number

of roughing, semi-finishing, & finishing passes. Area clearance of

stock from solid is carried out automatically.

- Specialist

modules available to suit your particular needs, e.g. Turbine Blade

refurbishment, Shoemaking.

- Post-processor files to

suit virtually every CNC on the market are part of the Tracecut package.

- A variety of CAD points

output formats such as DXF, IGES, VDA, ASCII are available

Typical Prices (exact price will depend on

options & exchange rates)

|

Description |

Euro € |

| Tracecut Software (Capture

Only Module) |

€9,250 |

| Tracecut Software (CNC

Programme CAM Module) |

€1,550 |

| Tracecut Software

(Turbine

Blade Module) |

€3,100 |

| Tracecut Software (Shoe

Module) |

€3,100 |

| Tracecut Software (Upgrade

from Older Version ) |

€3,000 |

Don't want to buy at the moment, or only

have a one-off requirement?

Then contact us for sub-contract options.

Click here

|