å

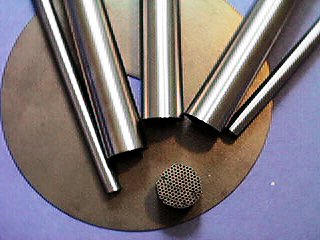

tto has combined it's uniquely formulated range of Precision Thin Cutting Wheels (thickness from 0.1 mm [0.004"] to 2.0 mm [0.080"]) with a range of High Technology Precision Cut-off Machines to offer a cost effective, accurate, method of cutting for tubes and rods up to 50 mm (2") diameters.åtto's Precision Cut-off Technology utilises very thin abrasive cutting wheels to give accurate, burr free, cut parts with minimum material loss and no alteration of material structure. Combining these technologies allows the cutting of tubes and rods to very tight length tolerances. Three machines are available to offer manual and automatic cutting with unequalled precision.

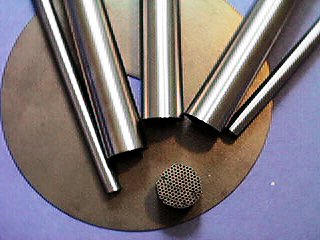

Bench Model Cutting-off Machine suitable for cutting tubes and solids up to 26 mm (1") diameter using thin cutting wheels from 0.1 mm (0.004") to 1 mm (0.040") in thickness.

![]() Maximum Spindle Speed: 3,600 rpm

Maximum Spindle Speed: 3,600 rpm

![]() Maximum Wheel Diameter: 152 mm (6")

Maximum Wheel Diameter: 152 mm (6")

![]() Wheel Bore Size: 12.7 mm (1/2") or 25.4 mm (1")

Wheel Bore Size: 12.7 mm (1/2") or 25.4 mm (1")

![]() Maximum Work Size: 26 mm (1") diameter

Maximum Work Size: 26 mm (1") diameter

This machine is ideal for cutting High Speed Steel, Stainless Steel Tubes and Rods, Magnetic and Ceramic materials, Hard Metals and for Metallurgical sampling.

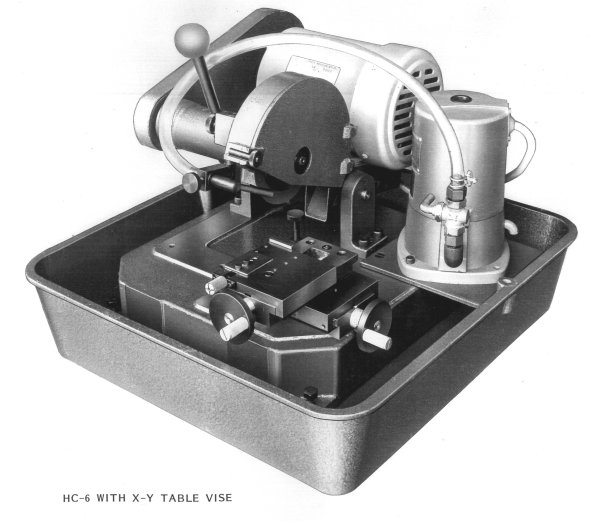

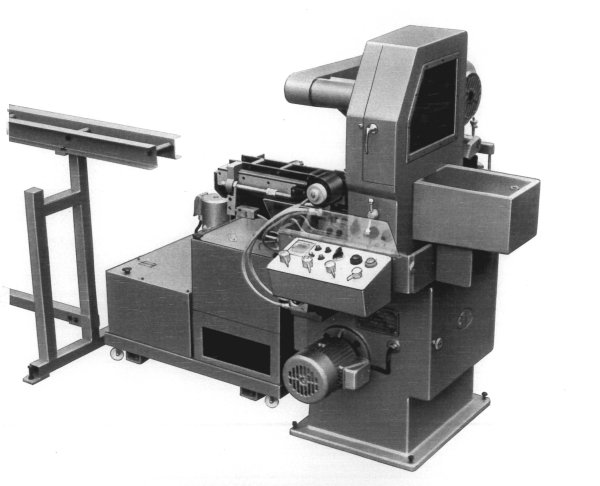

Fully Automatic Abrasive Cutting-off Machine:

Smooth hydraulic controls and automatic wheel wear compensation makes this machine extremely popular in the production of cut parts with repeatable accuracy in cut length and parallel cut surfaces. A standard length tolerance of +/- 0.05 mm (+/- 0.002") is achievable and closer tolerances have been obtained due to the ability to support the cutting disc above, during and after the cut cycle. Combining specially formulated cutting wheels it is possible to produce parts with a minimum or no burr, close tolerance on length and square cut surfaces with a minimum of material loss - rapidly.

![]() Maximum Work Diameter: 26 mm (1")

Maximum Work Diameter: 26 mm (1")

![]() Wheel Feed Rate: 2 to 2,000 mm/min (.008" to 80" /min.)

Wheel Feed Rate: 2 to 2,000 mm/min (.008" to 80" /min.)

![]() Wheel Rotation Speed: 2,800, 3,600, 4,100 or 5,200 r.p.m..

Wheel Rotation Speed: 2,800, 3,600, 4,100 or 5,200 r.p.m..

![]() Wheel Diameter: 205 mm (8")

Wheel Diameter: 205 mm (8")

![]() Wheel Bore Size: 25.4 mm (1")

Wheel Bore Size: 25.4 mm (1")

![]() Wheel Thickness: 0.3 - 1.2 mm (0.012" to .048")

Wheel Thickness: 0.3 - 1.2 mm (0.012" to .048")

![]() Cutting Length Accuracy: +/- 0.05 mm (+/- 0.002")

Cutting Length Accuracy: +/- 0.05 mm (+/- 0.002")

![]() Construction: Cast Iron Frame

Construction: Cast Iron Frame

This Machine is widely used in the cutting of Knockout/Ejector pins, Sprag or Bearing Parts, Extruded Shapes, Alnico Magnets, Hypodermic Needles, Precision Tubes in Inconel and Stainless Steel, Titanium parts, Ceramic Components and Hard Metal parts.

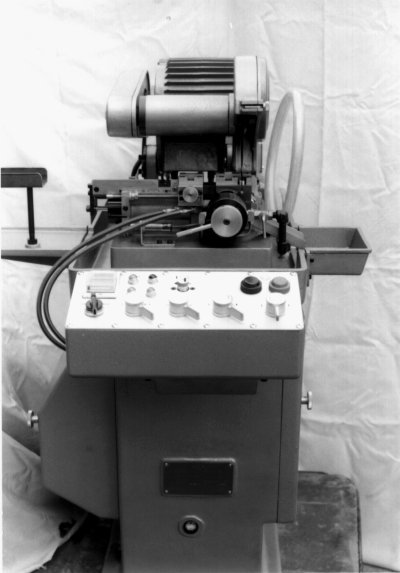

Fully Automatic Abrasive Cutting-off Machine similar to the AC-8 but capable of cutting parts to 50 mm (2") diameter. By supporting the 355 mm (14") diameter wheel above, during and below the clamping system it is possible to achieve a standard cut length tolerance of +/- 0.1 mm (0.004") either on single parts or bundled components to 50 mm (2") diameter/square.

![]() Maximum Work Diameter: 50 mm (2")

Maximum Work Diameter: 50 mm (2")

![]() Wheel Rotational Speed: 1,600, 2,500, 3,300 r.p.m.

Wheel Rotational Speed: 1,600, 2,500, 3,300 r.p.m.

![]() Wheel Diameter: 355 mm (14")

Wheel Diameter: 355 mm (14")

![]() Wheel Bore Size: 25.4 mm (1")

Wheel Bore Size: 25.4 mm (1")

![]() Wheel Thickness: 1.0 - 2.0 mm (0.040" - 0.080")

Wheel Thickness: 1.0 - 2.0 mm (0.040" - 0.080")

![]() Cutting Length Accuracy: +/- 0.1 mm (+/- 0.004")

Cutting Length Accuracy: +/- 0.1 mm (+/- 0.004")

![]() Construction: Cast Iron Frame

Construction: Cast Iron Frame