Diameter Range: 25 mm (1") to 700 mm (28")

Thickness Range: 0.1 mm (0.004") to 5 mm (0.200")

Thickness Tolerance: Standard +/- 0.05 mm (0.002"). Special Tolerance upon request

Bore Sizes: As requested

å

tto Precision Thin Cutting Wheels offer a fast, accurate, cost effective method to cut and slot Tubes and Rods with close tolerances, minimum burr and minimum material loss. Wheels are manufactured to suit a wide range of applications and cutting equipment, including the cutting of Thin Walled Tubes, Tungsten rods for electrodes, High Speed Steel, bearing parts, Magnetic materials and for the precision slotting of Collets, Tubes and Fountain Pen Nibs.

Manufacturers of components from extruded or cold drawn stock have found our precision cutting wheels an ideal solution for producing final parts, fast and accurately. The quality of finish eliminates further de-burring and grinding operations, while the thin wheel ensures minimum loss of material and a high degree of accuracy. Combining åtto thin wheels with our range of Precision Cutting Machines offers the ultimate cutting solution.

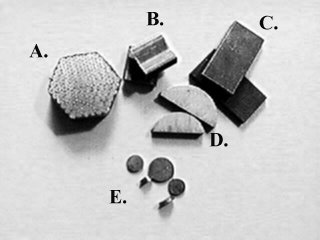

Sample Cut Parts

Wheels are formulated to meet your specific requirements and are designed to optimise wheel life without compromising finish or rate of cut. Grades are manufactured with premium abrasives including Aluminium Oxide, Silicon Carbide, White Aluminium Oxide and Green Silicon Carbide. Bonds are formulated in hardness from "E" to "Z" and grit sizes from 60 to 600.

Some of the common applications listed below will highlight the versatility of grades available from åtto. Some of our standard grades are listed, but we will advice you on your specific application and requirements upon request.

Common Applications:

Cutting Applications:

![]() Tungsten Rods for Contact Points (A150-P-R)

Tungsten Rods for Contact Points (A150-P-R)

![]() Tungsten Wire for Matrix printers and Electrodes (A120-F-R)

Tungsten Wire for Matrix printers and Electrodes (A120-F-R)

![]() Mould Ejector and Punch pins (A150-G-R)

Mould Ejector and Punch pins (A150-G-R)

![]() Extruded Profiles for:

Extruded Profiles for:

![]() Sprag Clutch Components

Sprag Clutch Components

![]() Trigger Parts (A120-R-R)

Trigger Parts (A120-R-R)

![]() Pump Vanes (A150-P-R)

Pump Vanes (A150-P-R)

![]() Stainless Steel Tubes for:

Stainless Steel Tubes for:

![]() Medical instruments, e.g. Hypodermic Needles, Endoscopes, etc..

Medical instruments, e.g. Hypodermic Needles, Endoscopes, etc..

![]() Heat Exchangers and Solar Panels (WA240-O-R)

Heat Exchangers and Solar Panels (WA240-O-R)

![]() Telescopic Aerials (A240-O-R)

Telescopic Aerials (A240-O-R)

![]() Measuring Instruments (A240-O-R)

Measuring Instruments (A240-O-R)

![]() Hydraulic Tubes for Aerospace and automotive applications

Hydraulic Tubes for Aerospace and automotive applications

![]() Inconel Tubes for:

Inconel Tubes for:

![]() High Temperature Probes

High Temperature Probes

![]() Glow Plugs

Glow Plugs

![]() Metallurgical Sampling

Metallurgical Sampling

![]() Minimum material alteration and mirror like finish reduces sample finishing costs. (A90-F-R, A120-E-R)

Minimum material alteration and mirror like finish reduces sample finishing costs. (A90-F-R, A120-E-R)

![]() Flexible Hoses and Cables:

Flexible Hoses and Cables:

![]() Control cables for bicycles, automotive and aerospace applications. (A120-R-R)

Control cables for bicycles, automotive and aerospace applications. (A120-R-R)

![]() Shower Hose (WA120-R-R)

Shower Hose (WA120-R-R)

![]() Armoured cables

Armoured cables

![]() Exotic Metals where material loss is a significant cost (A150-M-R)

Exotic Metals where material loss is a significant cost (A150-M-R)

![]() Titanium Tubes and Rods (C120-Q-R, GC320-O-R)

Titanium Tubes and Rods (C120-Q-R, GC320-O-R)

![]() Magnetic materials such as Alnico (A120-R-R, A120-F-R)

Magnetic materials such as Alnico (A120-R-R, A120-F-R)

![]() Transformer cores of Laminated Silicon Steel for "C" and "E" type cores.

Transformer cores of Laminated Silicon Steel for "C" and "E" type cores.

Slotting Applications

![]() Fountain Pen Nibs

Fountain Pen Nibs

![]() Aircraft parts including turbine blades

Aircraft parts including turbine blades

![]() Blades for Paper perforation

Blades for Paper perforation

![]() Collets (A60-S-R)

Collets (A60-S-R)

Special Applications

![]() Fluting of High Speed Steel Micro Drills

Fluting of High Speed Steel Micro Drills

![]() Side grinding of Carding Fabric - both fillets and tops (A90-R-R, A240-O-R, A600-O-R)

Side grinding of Carding Fabric - both fillets and tops (A90-R-R, A240-O-R, A600-O-R)

![]() Grooving Special Files

Grooving Special Files

![]() Grooving Resistors

Grooving Resistors

![]() Grinding Cutlery Fork prongs (A80-M-R)

Grinding Cutlery Fork prongs (A80-M-R)

![]() Wafering

Wafering

![]() Catalytic Converters

Catalytic Converters